News

charpy-v

The Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain-rate test which determines the amount of energy absorbed by a material during fracture. This absorbed energy is a measure of a given material's notch toughness and acts as a tool to study temperature-dependent ductile-brittle transition. It is widely applied in industry, since it is easy to prepare and conduct and results can be obtained quickly and cheaply. A disadvantage is that some results are only comparative.

The qualitative results of the impact test can be used to determine the ductility of a material.If the material breaks on a flat plane, the fracture was brittle, and if the material breaks with jagged edges or shear lips, then the fracture was ductile. Usually a material does not break in just one way or the other, and thus comparing the jagged to flat surface areas of the fracture will give an estimate of the percentage of ductile and brittle fracture.

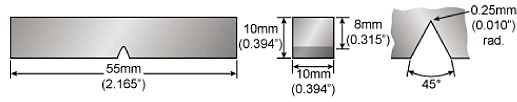

According to ASTM A370,the standard specimen size for Charpy impact testing is 10 mm × 10mm × 55mm. Subsize specimen sizes are: 10 mm × 7.5 mm × 55mm, 10 mm × 6.7 mm × 55 mm, 10 mm × 5 mm × 55 mm, 10 mm × 3.3 mm × 55 mm, 10 mm × 2.5 mm × 55 mm. Details of specimens as per ASTM A370 (Standard Test Method and Definitions for Mechanical Testing of Steel Products).

According to EN 10045-1, standard specimen sizes are 10 mm × 10 mm × 55 mm. Subsize specimens are: 10 mm × 7.5 mm × 55 mm and 10 mm × 5 mm × 55 mm.

According to ISO 148,standard specimen sizes are 10 mm × 10 mm × 55 mm. Subsize specimens are: 10 mm × 7.5 mm × 55 mm, 10 mm × 5 mm × 55 mm and 10 mm × 2.5 mm × 55mm.

CATEGORIES

LATEST NEWS

- High-Quality Izod Impact Test Machine | Impact Testing Equip2023-07-14

- Understanding the Science Behind an Impact Testing Machine2023-06-09

- Getting to Know the Impact Testing Machine2023-06-09

- Impact Testing Machines - Your Essential Partner for Premiu2023-05-25

- Impact Testing Machines - An Essential Tool for Accurate Ma2023-05-25

CONTACT US

Contact: Tamas Vibranyec

Phone: 0086-0579-7963961

Tel: 0086-0579-7963961

Email: [email protected]

Add: No. 1336.Bingwang Road Street,Yiwu City Zhejiang province CHINA