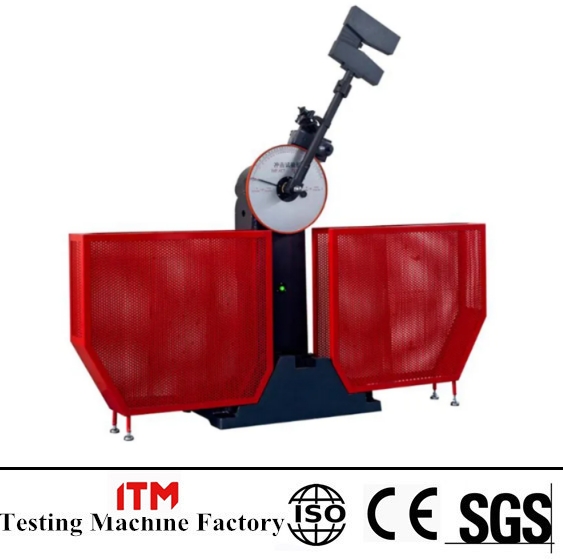

Semi-auto Impact Testing Machine

Semi-automatic Pendulum Impact Testing Machine - 副本

- impact testing machine

- impact testing machine price

- impact testing machine pdf

- charpy impact test lab report

- Product description: Looking for a reliable supplier of impact test machines and equipment? Explore our range of semi-automatic pendulum impact testing machines, including Charpy and Izod impact test machines, at competit

Introduction:

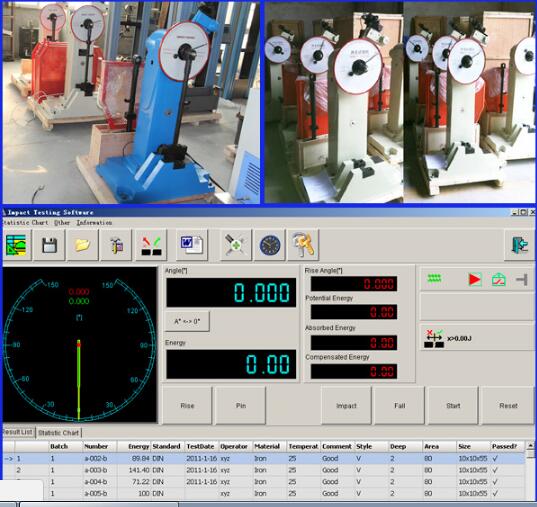

The Semi-automatic Pendulum Impact Testing Machine is a highly efficient and reliable testing instrument used to assess the impact resistance of various materials. It is widely employed in industries such as metallurgy, construction, and automotive manufacturing. This article will provide an overview of the machine, highlighting its main specifications and technical parameters.

Main Specifications:

- Impact Energy: The machine offers two impact energy options, namely 300J and 150J. This flexibility allows for testing materials with different strength requirements.

- Scale Range and Division Value: The energy range for testing is between 0 and 300J (or 0 and 150J). The division value per cell is 2J for 300J impact energy and 1J for 150J impact energy. This ensures accurate measurements during testing.

- Pendulum Moment: The pendulum impact energy is 300J or 150J, with corresponding pendulum moments of 160.7695N.m and 80.3848N.m, respectively. The pendulum moment determines the force applied during testing.

- Pendulum Advance Angle: The pendulum advance angle is set at 150º, ensuring consistent and reliable test results.

- Distance from Pendulum Center to Impact Point (Test Center): The machine maintains a distance of 750mm between the pendulum center and the impact point. This allows for precise and controlled testing conditions.

- Impact Velocity: The impact velocity is fixed at 5.2m/s, ensuring uniformity in test parameters.

- Span of Sample Support: The machine provides a span of 40mm for sample support, accommodating a variety of sample sizes.

- Arc Radius at the End of the Specimen Support: The arc radius at the end of the specimen support ranges from 1mm to 1.5mm, ensuring optimal support during impact.

- Inclination Angle of the Supporting Surface of the Specimen Support: The supporting surface of the specimen support is set at a 0º inclination angle, providing a stable platform for testing.

- Arc Radius of the Impact Knife: The impact knife features an arc radius between 2mm and 2.5mm, allowing for precise and controlled impact.

- Including Angle of Impact Knife: The impact knife has an including angle of 30º, ensuring accurate and consistent impact force application.

- Thickness of Impact Knife: The impact knife has a thickness of 16mm, providing stability and durability during testing.

- Specimen Specification: The machine is compatible with specimens measuring 10×10×55mm, enabling standardized testing.

- Weight of Testing Machine: The testing machine weighs approximately 450kg, ensuring stability during operation.

- External Dimensions of the Testing Machine: The dimensions of the machine are 2124×600×1340mm, optimizing space utilization.

- Power Supply: The machine operates on a three-phase four-wire system with a power supply of 50Hz and 380V, ensuring consistent performance.

- Motor Power: The machine’s motor power is 380V 180W, providing the necessary energy for testing.

- Minimum Resolution of Computer Display: The computer display offers a minimum resolution of 0.1J, ensuring precision in data analysis.

- Working Conditions: The machine operates optimally under the following conditions: room temperature between 10-35℃, relative humidity not exceeding 85%, absence of corrosive media and strong magnetic field interference, installation on a concrete foundation of at least 300mm thickness or a foundation weighing more than 880kg, and a machine base with an installation reference surface levelled within 0.5/1000.

Conclusion:

The Semi-automatic Pendulum Impact Testing Machine is a versatile and robust testing instrument that meets the industry’s requirements for impact resistance evaluation. With its comprehensive specifications and technical parameters, it provides accurate and reliable results, making it an indispensable tool for quality control and research and development purposes.

For more information of impact testing machine,please kindly contact with us .

PREVIOUS:helmet impact penetration machineNo next

CATEGORIES

- impact testing machine

- Manual Impact Testing Machine

- Semi-auto Impact Testing Machine

- Computer Impact Testing Machine

- Digital Impact Testing Machine

- drop weight impact test machine

- helmet impact testing machine

- incline impact test machine

- Low Temperature Chamber

- UV Notching Machine

- Notch Projector

- compression testing machine

LATEST NEWS

- High-Quality Izod Impact Test Machine | Impact Testing Equip2023-07-14

- Understanding the Science Behind an Impact Testing Machine2023-06-09

- Getting to Know the Impact Testing Machine2023-06-09

- Impact Testing Machines - Your Essential Partner for Premiu2023-05-25

- Impact Testing Machines - An Essential Tool for Accurate Ma2023-05-25

CONTACT US

Contact: Tamas Vibranyec

Phone: 0086-0579-7963961

Tel: 0086-0579-7963961

Email: [email protected]

Add: No. 1336.Bingwang Road Street,Yiwu City Zhejiang province CHINA